-

Our Commitment To Sustainability

Partnerships & Organizations Clover Imaging Supports

Business Call for a UN treaty on plastic pollution Sustainable Purchasing Leadership Council

Sustainable Purchasing Leadership Council Association for the Advancement of Sustainability in Higher Education

Association for the Advancement of Sustainability in Higher Education

-

Latest news

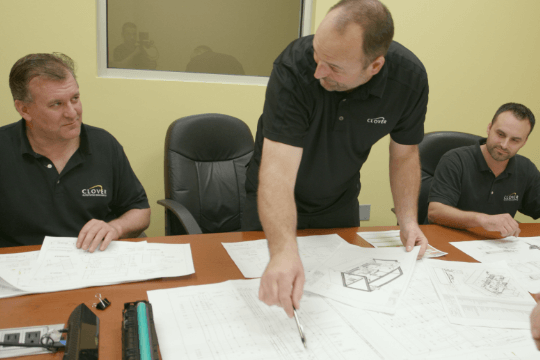

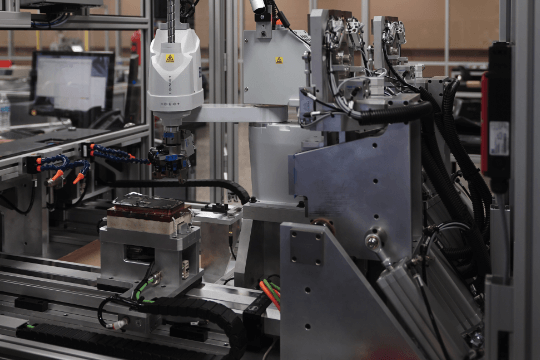

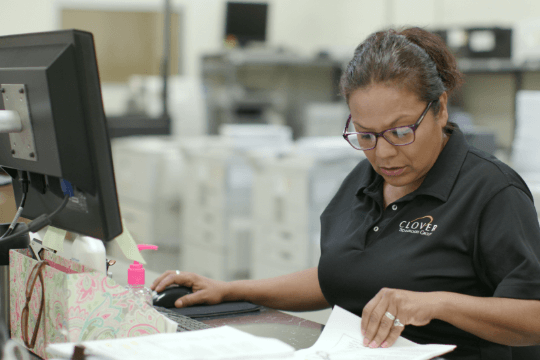

About Us

- Blog SHOP